|

Series

|

Model / Type

|

Symbol

|

Function Description

|

Pneumatic fitting

|

Action characteristic

|

Typical scenarios

|

|

3A Series (3/2 Way)

|

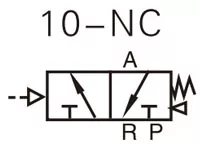

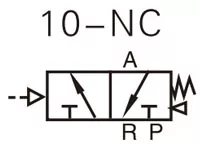

10-NC (Normally Closed)

|

|

Pilot ON: P →A

Pilot OFF: A →R (Exhaust)

|

3A110-M5/ 06: PC -01(G1/8)X2 piece,Silence G1/8 X1 piece

3A210-06/08 : PC -02(G1/4)X2 piece,Silence G1/4 X1 piece

3A310-08/10 : PC -03(G3/8)X2 piece,Silence G3/8 X1 piece

3A410-15 : PC -04(G1/2)X2 piece,Silence G1/2 X1 piece

|

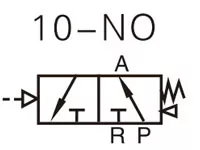

Spring Return:

NC/NO Switch: Actuates when air signal is present; resets by spring force when signal is removed.

|

Controlling Single Acting Cylinders

• Air Blow / Cooling Systems:Blow when there is a signal, stop when there is no signal

• Safety cut-off circuits (Fail-safe)

Immediately shut off the gas circuit if the signal source is lost.

|

|

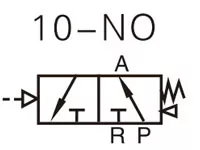

10-NO (Normally Open)

|

|

Pilot ON: A→ R (Exhaust)

Pilot OFF: P→ A

|

|

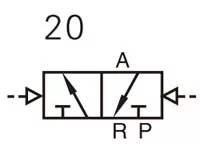

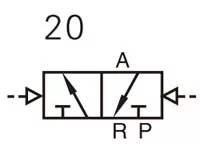

20 (Double Pilot)

|

|

Signal 1: Pilot ON: P →A

Pilot ON: A→ R (Exhaust)

Signal 2: Pilot ON: A→ R (Exhaust)

Pilot OFF: P→ A (Air In)

|

|

Memory/Bistable

Memory Function: Valve stays in the last switched position even if the signal is removed. Requires a counter-signal to reset.

|

Pneumatic Logic Circuits (Non-electric)

• Signal holding systems

• Hopper gate control (Open/Hold/Close)

|

|

4A Series (5/2 Way)

|

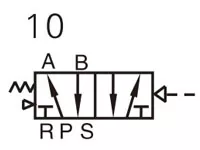

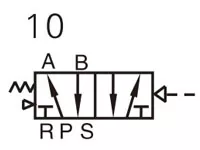

10 (Single Pilot)

|

|

Pilot ON: P → B, A → R

Pilot OFF: P → A, B → S

|

4A110-M5/ 06: PC -01(G1/8)X3 piece,Silence G1/8 X2 piece

4A210-06/08 : PC -02(G1/4)X3 piece,Silence G1/8 X2 piece

4A310-08/10 : PC -03(G3/8)X3 piece,Silence G1/4X2 piece

4A410-15 : PC -04(G1/2)X3 piece,Silence G1/2 X2 piece

|

spring Return

Standard Directional Control: Cylinder extends with signal; automatically retracts when signal stops.

|

Controlling Double Acting Cylinders

• Automatic Press Machines:The worker steps on the pneumatic foot valve to give a signal, and the cylinder presses down; Release your foot, the cylinder will automatically rebound

• Pneumatic Safety Doors:The door opens when there is a gas signal, and automatically closes when there is no signal.

|

|

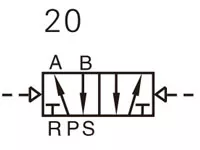

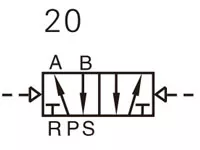

20 (Double Pilot)

|

|

Signal 1: P → A, B → S

Signal2: P → B, A → R

|

|

Memory/Bistable

Pulse Control: Requires only a short air pulse to switch and hold position. Ideal for long-distance signal transmission.

|

Long Conveyor Systems

• Clamping fixtures requiring Power-off Memory

• Flipping mechanism: After the cylinder reaches its end position, it remains in place without dropping even if the signal source is cut off

|

|

4A Series (5/3 Way)

|

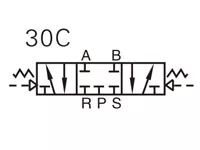

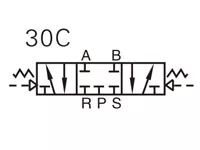

30C (Closed Center)

|

|

No Signal: All Ports Closed (A/B Blocked)

Signal 1: P → A ,B→ S

Signal 2: P → B,A→ R

|

4A130CEP-M5/ 06: PC -01(G1/8)X3 piece,Silence G1/8 X2 piece

4A230CEP-06/08 : PC -02(G1/4)X3 piece,Silence G1/8 X2 piece

4A330CEP-08/10 : PC -03(G3/8)X3 piece,Silence G1/4X2 piece

4A430CEP-15 : PC -04(G1/2)X3 piece,Silence G1/2 X2 piece

|

Stop & Hold

The cylinder stops immediately at its current position (acts like a brake).

|

Emergency Stops

• Vertical Lifting (Preventing drops)

• Mid-stroke positioning

|

|

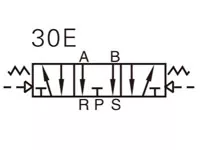

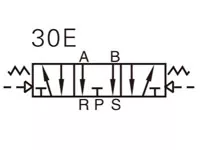

30E (Exhaust Center)

|

|

No Signal: A → R, B → S (Exhausting)

Signal 1: P → A,B→ S

Signal 2: P → B,A→ R

|

Free Movement

The piston loses pressure and can be moved manually by hand.

|

Manual Setup/Debugging:When the machine is stopped, the operator needs to manually move the cylinder to adjust alignment or change molds.

• Releasing residual pressure (Safety):

• "Floating" applications:follow-up mechanism: Used when the cylinder needs to move freely and follow an external force.

|

|

|

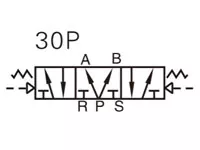

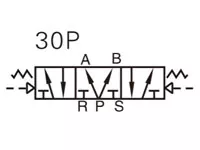

30P (Pressure Center)

|

|

No Signal: P → A, B (Pressurized)

Signal 1: P → A,B→ S

Signal 2: P → B,A→ R

|

Equilibrium/Extend

Maintains pressure balance (Note: Single-rod cylinders will slowly extend;If it is a dual-rod cylinder, it remains in a force-balanced state.).

|

Pressure Balancing Systems

• Preventing retraction in specific vertical setups(Less common):When installed vertically with the rod facing downward, the cylinder uses the differential area force to counteract gravity and prevent retraction.

|