What is pneumatic silencer?

During the operation of automatic machinery, noise often comes from three main sources: electromagnetic noise, mechanical noise, and the exhaust noise when compressed air is released from air cylinders. To effectively reduce this noise, a pneumatic silencer (air exhaust muffler) is widely used in pneumatic systems.

The OLK pneumatic silencers are installed on the exhaust ports of pneumatic control valves to lower the discharge sound. For example, the tower pneumatic muffler belongs to the absorption type. It uses sintered bronze beads as sound-absorbing material. When compressed air passes through the porous bronze structure, friction converts part of the pressure energy into heat, thereby reducing exhaust noise significantly.

As a professional pneumatic silencer manufacturer and supplier, OLK provides high-quality silencers and pneumatic accessories suitable for air cylinders, solenoid valves, and automation equipment.

|

Characteristic of pneumatic muffler

|

|

Model:

|

Advantages

|

Disadvantages

|

|

Adjustable type

|

can control exhaust flow

|

more expensive.

|

|

Tower type

|

best silencing effect

|

installation position is limited, not suitable for small solenoid valves or dense piping areas.

|

|

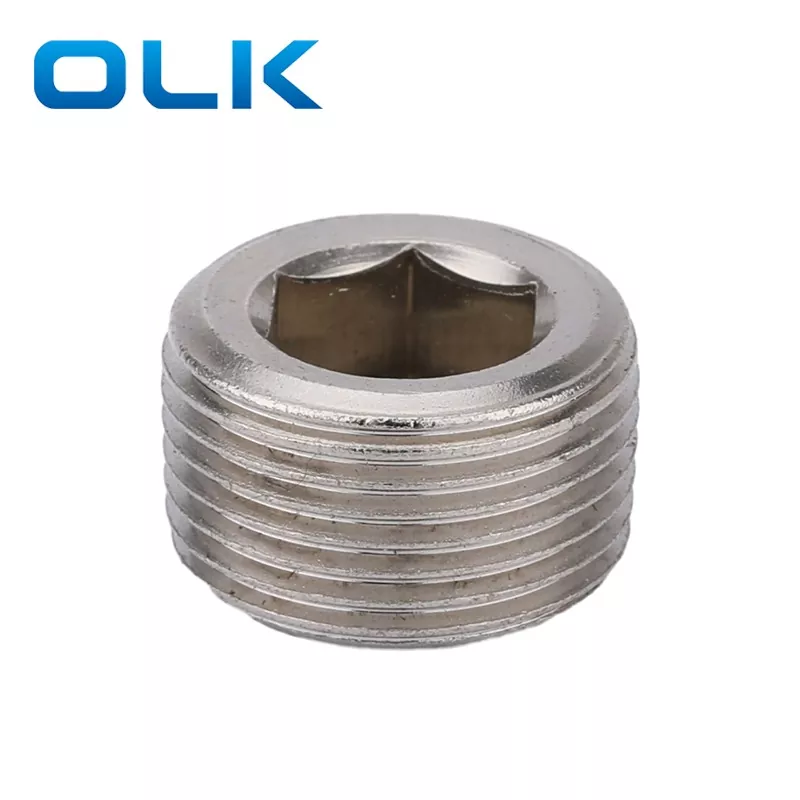

Flat type

|

for limited space

|

not suitable for large flow conditions.

|

|

Plastic type

|

lightweight, corrosion resistant

|

easy to clog, short service life.

|

How to choose pneumatic silencer?

When selecting a silencer, the first factor to consider is the application environment. The common types include:Adjustable type: allows regulation of exhaust flow.Tower type: provides the best noise reduction effect.Flat type: suitable for space-limited installations.Plastic type: lightweight and corrosion resistant.Most people usually choose the tower-type silencer, which is the best-selling type

The second step is to choose the silencer size according to the valve’s port thread (e.g., G1/8, G1/4, G3/8, G1/2, G3/4, G1).

NOTICE:

·If the pores become clogged, clean or replace the pneumatic silencer to prevent reduced flow, slower actuator speed, and degraded response performance.

·When the sound-absorbing material is PP, P, or PVF, avoid using it in environments with organic solvents.

·Ensure that water is separated from the exhaust pipeline as much as possible; otherwise, moisture in the compressed air may freeze on the silencer, increasing exhaust resistance.

·For pneumatic cylinders with large size, high pressure, and long stroke, the exhaust volume is very large and fast, so the silencing effect is not very good (it may reduce only about 15–20 dB). On the contrary, for cylinders with lower pressure and shorter stroke, the exhaust volume is much smaller, resulting in a much better silencing effect (it can reduce noise by around 35 dB). The purpose and actual effect also depend on the noise level of the discharged air.